Written by: Collin Fields, Marketing & Communications Manager, OWA

The global energy landscape is undergoing a dramatic transformation. It’s driven by rising energy demands from electrification and data centers along with the urgent need to decarbonize our economies and mitigate the impacts of climate change. Offshore wind energy has emerged as a critical component of this transition, offering a clean, abundant, and increasingly cost-competitive alternative to fossil fuels. However, the full potential of offshore wind has been constrained by the limitations of traditional fixed-bottom installations, restricting development to shallower coastal waters. Floating offshore wind turbines represent the future of offshore power, unlocking access to vast, untapped wind resources in deeper waters, ushering in a new era of clean energy generation.

Floating offshore wind offers significant advantages over its fixed-bottom counterpart, including higher capacity factors due to stronger and more consistent winds. Traditional offshore wind turbines are economically and technically limited by water depth and complex seabed conditions. Once the water depth reaches beyond 200 feet (60 meters), monopile and jacket foundations are no longer suitable to support offshore wind turbines which significantly restricts the geographic scope of development. Floating platforms, anchored to the seabed by flexible mooring systems, overcome these constraints, enabling turbines to be deployed in deeper waters where wind resources are significantly more abundant and consistent. Crucially, around 80% of the world’s exploitable offshore wind resources reside in waters deeper than 60 meters, a domain currently inaccessible to fixed-bottom installations. Floating offshore wind thus represents a critical pathway to harnessing this vast, untapped energy resource.

Global Development

Floating offshore wind projects are gaining momentum globally, with significant development in Europe, the United States, and Asia. With 270 MW of operational capacity in 2023, the global project pipeline has surged to 244 GW, demonstrating substantial industry momentum. While the technology is relatively new, it offers the potential to access deeper, windier waters than traditional fixed-bottom turbines. Europe currently leads in operational floating wind capacity and projects in earlier development stages, while the US has a large prospective capacity in the planning stages (mostly off the coast of California).

According to a recent market report from the Global Wind Energy Council (GWEC), Norway, the UK, China, France and Portugal are the top five markets in net floating wind installations today. By the end of 2034, China, the UK, South Korea, Norway and Portugal are likely to be the top five floating Markets. GWEC Market Intelligence predicts floating wind to become fully commercialized by the end of this decade, with multi-GW levels of new installations expected from 2031 onward. A total of 278 MW net floating wind was installed globally at the end of 2024: 101 MW in Norway, 78 MW in the UK, 40 MW in China, 27 MW in France, 25 MW in Portugal, 5 MW in Japan and 2 MW in Spain.

Over 50 different floating foundation models for offshore wind turbines are currently in development, with popular designs including spar, tension leg platforms, semisubmersibles, damping pools, and barges. A key advantage of these structures is their ability to be assembled on land and then towed out to deep water locations, sometimes over 300 miles from shore, without a significant reduction in their design life. These massive foundations, which can be as large as a football stadium, offer a solution for harnessing wind energy in areas where traditional foundations are not feasible.

Image from RWE

Image from RWE

Despite their potential, the widespread deployment of floating offshore wind faces several significant hurdles. Technologically, there are ongoing challenges such as determining whether offshore substations should be floating or fixed-bottom, managing potential electricity losses over the very long dynamic cables required to transmit power to shore, and deciding between steel and concrete for foundation construction. Major restrictions also exist in terms of infrastructure and supply chain. The development of this technology is still in its early stages, and there is a critical lack of highly specialized ports with large quaysides, deep-water access, and freedom from obstructions like bridges or hurricane barriers, which are necessary for the assembly and deployment of these enormous structures.

To overcome these challenges and test the feasibility and performance of these developing technologies, a variety of “Pilot Projects” are being built around the world. They are designed as demonstrations to prove the validity of the technology and testing grounds to study new concepts. They are typically comprised of a small number of turbines (1-4 units) and are often scaled down to lower costs. The main purpose is to prove that these technologies are efficient, safe, and ready to be built at scale. They are also put to the test for several years to help identify faults and design errors that need to be improved upon. These pilots serve as an opportunity to test out new floating offshore wind technology in a real world setting so that future developments can be better informed and prepared for the complexities of deep water wind energy.

Since there are hundreds of planned floating offshore wind projects in various stages of development, the remainder of the article covers the operating pilot projects around the world that have set the stage for the future of commercial scale ocean energy.

China

Yangxi West Shapa: The Yangxi West Shapa floating offshore wind project is a 400 MW initiative by China Three Gorges (CTG). It’s located in the South China Sea off the coast of Yangjiang City, Guangdong Province. The project features China’s first floating wind turbine, a 5.5 MW MingYang Electric Smart Energy unit, designed to withstand typhoons, installed on a Wison Engineering Ltd. steel semisubmersible platform. The project is a pilot for shallow water floating wind technology. The unit has been fully assembled at the company’s factory in Yangjiang, Guangzhou, a small port city about 130 miles southwest of Hong Kong.

The prototype was towed out and installed at the China Three Gorges Yangxi Shapa III offshore wind farm as a technology demonstrator for testing. It operates alongside 31 of Yangjiang’s 6.5 megawatt bottom-fixed offshore wind turbines.

Image from MingYang Smart Energy

Image from MingYang Smart Energy

Wenchang Deep Sea Float: The Haiyou Guanlan demonstration project is located near the Wenchang oilfields in the western part of the South China Sea, 136 kilometers offshore in a water depth of 120 meters. The 7.25 MW floater is the first in China that supplies power to an offshore oilfield.

According to CNOOC, the floating wind turbine is also the world’s first semi-submersible “double hundred” deep-sea floating wind project, operating in a water depth of over 100 meters and with an offshore distance of over 100 kilometers.

With an installed capacity of 7.25 MW, the platform can produce up to 22 GWh of electricity, equivalent to saving nearly 10 million cubic meters of natural gas and reducing carbon dioxide emissions by 22,000 tones per year, according to the Chinese oil giant.

The wind turbine is reported to weigh over 11,000 tons with its foundation and was positioned nearly 85 miles offshore. It is floating in a position with a water depth of more than 325 feet. The overall height of the structure stands more than 650 feet. The Chinese engineer placed the turbine atop a triangular floating foundation with three side columns and one center post to hold the wind turbine. The ballast system weighs 4,000 tons.

Wenchang Deep Sea Float, image from Maritime Executive (CNOOC)

Wenchang Deep Sea Float, image from Maritime Executive (CNOOC)

Longyuan Nanri Island: Built within the National Sea Ranch Demonstration Zone on Nanri Island, located in Putian, Fujian Provence of China, the project features three-column semi-submersible floating platforms, each one supporting a 4 MW offshore wind and lightweight solar modules that are installed in the area with water depth of around 35 meters. It is a first-of-its-kind hybrid project developed by China Longyuan Power Group Corporation Limited and Shanghai Electric Wind Power Group Co., Ltd. Once operational, the hybrid floating offshore wind project can generate 96,000 kWh of electricity daily at full capacity, equivalent to the daily energy consumption of 42,500 people, according to Shanghai Electric Wind Power Group.

Since its commissioning, the platform has operated stably, with wind turbine reliability maintained above 95% and a record of 120 consecutive hours of full-capacity power generation. Meanwhile, the aquaculture zone generates millions of yuan in revenue per production cycle, demonstrating a new model of coordinated development between “green energy and blue food production”. The platform has also withstood multiple typhoon tests, validating its structural stability and reliability.

Image from Shanghai Electric

Image from Shanghai Electric

Qingzhou IV Floating Demo: Guangdong Yangjiang Qingzhou Four Wind Farm is a 505 MW offshore wind power project in the South China Sea, Guangdong, China. According to GlobalData , who tracks and profiles over 170,000 power plants worldwide, the project is being developed in multiple phases. The turbines are mounted on fixed jacket foundations and are interconnected by a 35kV inter-array cable. Phase I is equipped with China Ming Yang Wind Power Group MySE11-230 turbines. The phase consists of 25 turbines with 11 MW nameplate capacity. Phase II will be equipped with China Ming Yang Wind Power Group MySE12-242 turbines. The phase consists of 18 turbines with 12 MW nameplate capacity.

Mingyang Smart Energy’s OceanX, which the company says is the world’s largest single-capacity floating wind power platform, has started operating at the Qingzhou IV offshore wind farm in Yangjiang, China, where it was installed in the summer of 2024. The dual-turbine, V-shaped floater operates autonomously, starting up with its own power systems, and has been tested for off-grid stability, according to Mingyang. OceanX, which features two MySE8.3-180 hybrid drive wind turbines, each with a capacity of 8.3 MW, was towed to the site off Yangjiang in August after its construction was completed in Guangzhou in July. The platform is 219 meters tall and 369 meters wide, has a single-point mooring system and was designed to withstand typhoons with 360° load considerations. The platform’s turbines feature counter-rotating blades which Mingyang says increases power generation by 4.29 %. With a generation capacity of 16.6 MW, the floater is capable of producing 54 GWh annually, enough to power 30,000 households, according to the company.

OceanX, image from MingYang Smart Energy

OceanX, image from MingYang Smart Energy

Bigger Floating Turbines Underway

In January 2025, the Chinese state-owned company CRRC successfully hoisted its new 20 MW floating offshore wind turbine, the “Qihang,” at a test site in Shandong. The company claims this is the world’s largest power-class floating wind turbine to enter the testing phase.

Having rolled off the production line in October 2024, the massive unit features a rotor diameter of 260 meters (853 feet) and a hub height of 151 meters (495 feet). CRRC reports that a single rotation can power a family’s electricity needs for 2 to 4 days and that the turbine is designed with advanced stability and typhoon-resistant technologies.

The “Qihang” will now undergo extensive testing across more than 200 points to assess its performance under various sea conditions. This development is part of China’s broader strategy to dominate the global offshore wind sector and become a key supplier for international projects. Following certification, the turbine is planned for deployment in deep-sea areas for grid-connected power generation.

While its 20 MW capacity surpasses prototypes from competitors Envision Energy (16.7 MW) and DONGFANG ELECTRIC CORPORATION (DEC) (18 MW), another Chinese company, Mingyang Wind Power, is developing an even larger 22 MW unit expected to be completed this year.

France

Floatgen: Built around a European consortium of 7 partners, Floatgen is a 2MW floating wind turbine demonstrator installed off the coast of Le Croisic on the offshore experimentation site of the Ecole Centrale de Nantes (SEM-REV). This project is being supported by the European Union as part of the FP7 program. Floatgen is France’s first offshore wind turbine. 5 000 inhabitants are supplied with its electricity. It utilizes BW Ideol’s patented Damping Pool® floating foundation (36 square meters, draught of 7.5 meters), the world’s first floating barge designed for offshore wind and 6 synthetic fiber (nylon) mooring lines, a world first for a permanent mooring system of this size.

Project Facts:

- Performance: Floatgen has demonstrated exceptional performance, including a high availability rate (92.18% average between January 2021 and January 2024) and impressive power output. It has also successfully withstood challenging weather conditions.

- Achievements: Floatgen was France’s first offshore wind turbine. Its operational life was extended for another five years due to its positive results. It has also powered the world’s first offshore hydrogen plant.

- Technology: It utilizes BW Ideol’s patented Damping Pool® technology, which is a concrete, ring-shaped floating platform designed for stability and cost-effectiveness.

- Turbine: It features a 2MW Vestas V80 wind turbine.

- Location: Installed at the SEM-REV offshore test site, approximately 20 km off the coast of Le Croisic, in water depth of 33 meters.

- Commercial Operation Date: September 2018.

FloatGen, image from BW Ideol

Provence Grand Large (PGL): Provence Grand Large is the first floating wind project in France, located 17 kilometers off the coast of Port Saint Louis du Rhône (near Marseille) built by EDF in partnership with Enbridge and CPP Investments. It’s also the first project in the world to use a tension leg floater developed by SBM Offshore in cooperation with IFP Energies nouvelles. SBM Offshore’s floater results in reduced motion and stress on the turbine components, hence is compatible with all wind turbines. The minimal footprint of this type of floater represents also an optimal solution for the development of floating wind farms. Provence Grand Large is expected to produce the equivalent of the annual electricity consumption of 45,000 inhabitants

The 25 MW pilot farm is composed of three tension leg floaters, each supporting 8.4 MW wind turbine generator supplied by Siemens Gamesa. The platforms use deep-water anchoring technology adapted from oil and gas operations. The dynamic cables, built by Prysmian, which follow and adapt to the movements of the platforms, transport the electricity produced by the Provence Grand Large wind turbines. Connected to subsea and then terrestrial cables, they ensure the transport of the electricity produced to the onshore connection station operated by RTE.

Installation of the last turbine was completed in October 2023, with the project delivering its first power to the national electricity grid a year later. On June 5th, 2025, the project was fully commissioned.

“By contributing to the diversification of our renewable energy sources, this pilot farm plays an active role in France’s energy transition, while also supporting the emergence of a cutting-edge industrial sector around these innovative technologies. I would like to thank all the local stakeholders, as well as the teams at EDF Renewables and our partners, Enbridge and CPP Investments, for their commitment,” said Bernard Fontana, Chairman and CEO of EDF Group.

Province Grand Large, image from EDF

Province Grand Large, image from EDF

Éoliennes Flottantes du Golfe du Lion (EFGL) Leucate: Developed by OW Ocean Winds and Banque des Territoires. assembled at Port-La Nouvelle ahead of its installation at the project site located 16 kilometers offshore Leucate and Barcarès.

The 30 MW EFGL floating offshore wind farm will consist of three Vestas V164-10.0 MW turbines supported by Principle Power’s WindFloat semi-submersible floating foundations, which are delivered by Eiffage Métal, Smulders, and their subcontractor GEODIS .

EFGL is a pilot project which will also inform the next generation of floating offshore wind farms in the Mediterranean, including the Eoliennes Flottantes d’Occitanie (EFLO), a 250 MW floating offshore wind project that is also owned by Ocean Winds and Banque des Territoires.

Ocean Winds completed the installation of the third and final turbine at the (EFGL) project on September 4th, 2025. The Vestas turbines stand ready for the final stage of cable and grid connection works which will be carried out by the French transmission system operator (TSO) Réseau de Transport d’Électricité (RTE) before the turbines begin delivering renewable energy to approximately 50,000 inhabitants each year. The project is also the world’s first nature-inclusive floating wind farm, with artificial marine habitats (bio huts) installed at sea to enhance biodiversity.

EFGL Leucate, image from Ocean Winds

EFGL Leucate, image from Ocean Winds

Japan

Goto Sakiyama (Goto City Offshore Wind Power Generation Project): The Goto Sakiyama floating wind project, officially known as the Goto City Offshore Wind Power Generation Project, is a 524 MW offshore wind power project located in the East China Sea, near Goto City, Nagasaki, Japan. The project is being developed in multiple phases by a consortium including Japan Renewable Energy Corporation, OSAKA GAS CO., LTD., INPEX CORPORATION, The Kansai Electric Power Co., Inc., and Chubu Electric Power Co., Inc.

Initially scheduled to begin operations in January 2024, the project has been delayed by two years due to construction issues. The postponement was necessary after defects were discovered in the project’s floating structures during onshore construction, requiring work to be corrected and restarted. The project is now officially aiming for the January 2026 start-up. The 16.8-MW development is on track to start operations in January 2026. Each of the eight (8) Hitachi 2.1 MW wind turbines will be 176.5 m tall, with a rotor diameter of 80 m.

The wind turbines are supported by hybrid SPAR-type, three-point mooring floating foundations. The hybrid SPAR-type foundations is a type of structure featuring state-of-the-art technology developed in Japan. By using a hybrid of steel and concrete (steel in the upper part and concrete in the lower part) for the elongated spar-type floating body, the wind turbine’s center of gravity is lowered, resulting in improved stability. This has also resulted in significant cost reductions with the use of purely domestic concrete.

Project Facts

- Planned Capacity: 524 MW.

- Location: East China Sea, Nagasaki, Japan.

- Status: Under construction, with a revised operational startup date of January 2026.

- Developer: Goto Floating Wind Farm LLC Consortium.

- Key Members: Japan Renewable Energy Corporation, OSAKA GAS CO., LTD., INPEX CORPORATION, The Kansai Electric Power Co., Inc., and Chubu Electric Power Co., Inc.

- Delay: Initial commercial operation date of January 2024 was postponed to January 2026 due to defects in the floating structures.

- Turbine Type: The project is likely to utilize 10-15 MW turbines in later phases, potentially replacing the initially planned 5 MW turbines.

- Transmission: The generated electricity will be connected to Kyushu Electric Power’s grid to supply the Goto Islands.

- Project History: The project involves the development of floating wind turbines, with a 2 MW prototype (Sakiyama 2 MW Floating Wind Turbine) already in operation.

Image from Goto City

Image from Goto City

Hibiki: The Hibiki floating wind project is Japan’s first barge-type floating wind turbine and the second floating wind turbine to be commercialized in the country. It’s a Aerodyn SCD 3 MW, two-bladed turbine installed on BW Ideol’s Damping Pool floating foundation, located 15 kilometers off the coast of Kitakyushu. It was commissioned in May 2019.

Originally a demonstration project by New Energy and Industrial Technology Development Organization (NEDO), it is now operated by Hibiki Floating Wind Power (HFWP), a company established by Glocal after the demonstration phase concluded in March 2024. The project aims to contribute to Japan’s renewable energy goals and reduce reliance on conventional energy sources. The Hibiki project is a significant step in Japan’s efforts to develop and deploy floating wind technology, which is crucial for accessing deeper waters and expanding offshore wind capacity.

Image from NEDO / BW Ideol

Image from NEDO / BW Ideol

Norway

Unitech Zefyros (Hywind Demo): Unitech Zephyros, formerly known as Hywind Demo, is a 2.3 MW floating wind turbine originally developed and installed by Equinor (formerly Statoil) in 2009. It was the world’s first commercial-scale floating wind turbine and is now owned and operated by Unitech Offshore for research and development purposes.

The turbine is located at the METCentre test site near Karmøy, Norway. It has been generating power since 2009, maintaining an average of 99% uptime during 2022. It was also the first floating wind turbine to have a helicopter deck mounted to it. The demonstration projects utilizes a spar-buoy type floating foundation. This foundation consists of a slender, cylindrical steel structure that is anchored to the seabed with mooring lines. The cylinder is partially submerged and filled with ballast (water and rocks) to ensure stability.

It now serves as a research and development platform, allowing for testing of new technologies and training in the field of floating offshore wind. Unitech plans to use Zefyros as a hub for connecting new turbines and testing various R&D initiatives. The turbine continues to supply electricity to the local grid, powering approximately 400 households annually.

Image from Unitech Zefyros-One

TetraSpar Demo: The project is carried out in a partnership between Shell, RWE, Tepco Renewable Power, and Stiesdal Offshore.

The TetraSpar is a floating foundation that uses a buoyant steel structure with a suspended keel for stability. A ballast-filled keel is suspended beneath the main structure, lowering the center of gravity and providing stability, similar to a spar buoy. It’s designed for industrialization, utilizing modular, tubular steel components that can be manufactured in factories and assembled in ports. It is expected to offer important competitive advantages with its potential for lean manufacturing, lean assembly and installation processes, and low material costs.

The foundation and keel were assembled using no welding at the Port of Grenaa in Denmark. A 3.6 MW Siemens Gamesa wind turbine was mounted on the foundation following its launch in the harbor basin. In July 2021 the combined structure was towed to the test site at the Marine Energy Test Centre, 10 kilometers off Karmøy in Norway. Here, the TetraSpar Demonstrator was commissioned and is in full operation at a water depth of 200 meters.

Over three years of stable operation, the TetraSpar Demonstrator has delivered extensive and valuable data to its owners. The demonstration project validates the concept of a fully industrialized approach to floating wind design and demonstrates the immense potential of floating offshore wind power generation. In the first two years of operation, the availability was recorded at 97% and 98.3%, respectively. For 2024, the availability has increased to 99.5% with a capacity factor of almost 63%.

Images from Stiesdal

Hywind Tampen: Hywind Tampen is the world’s first floating wind farm built specifically to power offshore oil and gas installations, and is now supplying electricity to Equinor’s oil and gas fields Snorre and Gullfaks in the Norwegian North Sea. With a system capacity of 94.6 MW it is also the world’s largest floating offshore wind farm and an important step forward in industrializing solutions and reducing costs for future offshore wind power projects.

Hywind Tampen is a test bed for further development of floating wind, exploring the use of new and larger turbines, installations methods, simplified moorings, concrete substructures and integration between gas and wind power generation systems.

The floating wind farm consists of 11 wind turbines which have been upgraded from 8 to 8.6 MW. Although the export system capacity and the platforms have not been upgraded accordingly, the increased capacity should contribute to an increased overall yearly production due to increased uptime.

Facts

- Total system capacity: 94.6 MW

- Location: About 140 km off the Norwegian coast

- Water depth between 260 and 300 meters

- Installed on floating concrete spar structures with a shared anchoring system

- The wind turbines are connected in a 2.5 km-long inter-array network with a capacity of 66 kV

- Commenced producing power in the third quarter of 2022 and in full operation as of summer 2023

PORTUGAL

WindFloat Atlantic by WindPlus EDP: Continental Europe’s first floating offshore wind farm, located off the coast of Viana do Castelo, Portugal. Since February 2020, WindFloat Atlantic has been supplying the Portuguese electricity grid with innovative clean energy. Commissioned in 2020, this offshore wind farm uses cutting-edge technology, which enabled the installation of floating platforms in previously inaccessible water depths, where abundant wind resources can be harnessed. WindFloat Atlantic (WFA) has exceeded energy production estimates during its five years of operation, with a total output of 345 GWh.

Project Facts:

- 25 MW Installed Capacity

- Supply electricity to 25,000 Portuguese households/year

- Avoids the emission of 33,000 tons of CO2/year

- 3 wind turbines, 8.4 MW each

- 3 WindFloat floating platforms

- In operation since 2020

- Designed for 25 years of operation

- 18 km of the coast of Viana do Castelo, Portugal

- Around 100m water depth

Image from Principle Power

Image from Principle Power

Spain

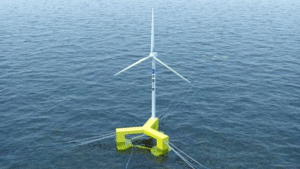

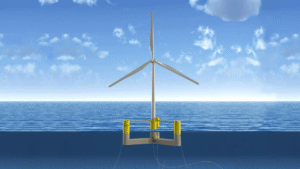

DemoSATH by RWE & SAITEC: The DemoSATH project uses a 2 MW turbine which was assembled in the port of Bilbao in northern Spain. The platform, including the turbine, has been towed to the BiMEP test site, which is 2 miles offshore with a water depth of 85m. Hybrid mooring lines, composed of chains and fibre, anchored to the seabed hold the unit in position. It has been in operation since September 2023. The SATH concept is a concrete twin-hull barge structure, made of modular, pre-fabricated components. The design has a single point of mooring, which means it aligns itself to the current and wave direction.

Image from RWE

Image from RWE

UK

Hywind Scotland by Equinor (Hywind II): The world’s first floating wind farm, the 30 MW Hywind Scotland pilot park, has been in operation since 2017. Equinor and partner Masdar invested NOK 2 billion to realise Hywind Scotland, achieving a 60-70% cost reduction compared with the Hywind Demo project in Norway. Hywind Scotland started producing electricity in October 2017. Each year since Hywind Scotland started production the floating wind farm has achieved the highest average capacity factor of all UK offshore windfarms, proving the potential of floating offshore wind farms. Suitable for harsh conditions, the simple three-line mooring system, patented motion control reduces fatigue, increases production.

Project Facts:

- The world’s first floating offshore wind farm, with five 6 MW Siemens Gamesa turbines

- Pilot park covering around 4 square kilometers

- Installed capacity: 30 MW

- Diameter 154 m

- Maximum height, base to turbine: 253 m

- Water depth: 95-120 m

- Spar-type substructure

- Standard offshore wind turbine

- Powering ~35,000 UK homes

- Export cable length: Ca. 30 km

- Average wave height: 1.8 m

Kincardine by Flotation Energy: The Kincardine Offshore Windfarm, 15 km off the coast of Aberdeen, Scotland, is the world’s largest grid-connected floating wind project. The Kincardine array’s first turbine started generating in 2018 and the project was completed by late summer 2022. The 50 MW project consists of 5 Vestas 9.5 MW turbines and 1 Vestas 2 MW turbine. The Kincardine project uses the WindFloat steel semi-submersible floating foundations designed by Principle Power.

Image from Floatation Energy

Image from Floatation Energy

U.S. Projects (Under Development)

Cademo (Lease granted): Developed by Floventis Energy, a joint venture between Cierco Energy and SBM Offshore. CADEMO’s turbines will be visually similar to conventional onshore wind turbines, but will be taller and will feature larger blades to produce higher generation capacities. Each turbine will be capable of generating 12-15 megawatts (MW) of renewable electricity for a maximum project capacity of up to 60 MW.

The four wind turbines will be connected with inter-array cables, and a subsea export cable will be installed under the seafloor to an onshore cable landing site at Vandenberg. An onshore overhead power line will be installed from the landing site to a new substation located adjacent to PG&E’s existing Surf Substation. The project will be located about 2.8 miles off Point Arguello, adjacent to Vandenberg Space Force Base. The location is unique to California’s 840 miles of coastline.

Here’s why the site was chosen:

- It does not have proximity to housing areas and thus has very little visual impact on local residents, and the closest accessible location for the public is 8.3 miles away.

- It does not overlap any sanctuary or natural-resource protected area.

- The adjacent coastline is not a wilderness or scenic area – instead it is part of a military-industrial space launch complex under control of the U.S. Department of Defense, with strictly limited access for civilians.

- The project site is accepted by the Defense Department and Vandenberg base authorities.

- It provides exposure to many fish and wildlife species also present in deeper federal waters of the Morro Bay auction area.

- It is close to shore to allow scientists and researchers easy access to environmental testing, equipment and mitigation measures.

- It has good wind resources & the location has nearby available electrical grid connections.

Maine Aqua Ventus I by RWE / Diamond Offshore / Terra Volturnus (permit applied): The Maine Aqua Ventus I project is a 12 MW floating offshore wind demonstration project utilizing the University of Maine’s VolturnUS concrete semisubmersible hull technology. The project will consist of a single semisubmersible concrete floating platform that will support a commercial 10–12 megawatt wind turbine and will be deployed in a state-designated area 2 miles south of Monhegan Island and 14 miles from the Maine coast. The purpose of the demonstration project is to further evaluate the floating technology, monitor environmental factors and develop best practices for offshore wind to coexist with traditional marine activities. It will supply clean, renewable electricity to the Maine grid. The project is a partnership between RWE Renewables, Diamond Offshore Wind, and the University of Maine. It aims to demonstrate the viability of floating offshore wind technology and its potential for large-scale deployment in the US. The project is located 2 miles south of Monhegan Island, 14 miles from the Maine coast.

Simulated image of Aqua Ventus I from UMaine

Simulated image of Aqua Ventus I from UMaine

Sources

United States

- University of Maine Floating Offshore Wind Demonstration Project

- California Demo Project (CADEMO)

- 4C Offshore Wind Database

United Kingdom & Europe

- Salamander Floating Wind

- Kincardine Offshore Wind Farm

- Hywind Scotland – Equinor

- Hywind Tampen – Equinor

- DemoSATH – RWE

- Floatgen Demonstrator – BW Ideol

- SEM-REV Offshore Test Site

- Provence Grand Large – EDF Renewables

- Provence Grand Large – Commissioning (CPP Investments)

- Provence Grand Large Installation – OffshoreWind.biz

- First 10 MW Floating Turbine in Mediterranean

- SBM Offshore – Floating Wind Units

Japan

- INPEX Floating Wind Farm (2026 Startup)

- Structural Defects Delay Japan’s First Floating Wind Farm

- TODA Corporation – Sakiyama 2MW Project (PDF)

- Japanese Demonstrator – BW Ideol

- TetraSpar Demonstration – Stiesdal

- Zephyros Offshore

China

- MingYang Floating Offshore Wind Platform

- Deepwater Floating Wind Connected to Wenchang Oil Field

- China’s First Deep-Sea Floating Offshore Wind Turbine

- Nanri Island Offshore Wind Project

- Hybrid Floating Wind Project in China

- MingYang 16.6 MW Dual-Turbine Floating Platform

- CRRC – World’s Largest Floating Offshore Wind Turbine

- 20 MW Floating Wind Turbine Testing

Industry & Market References